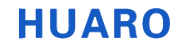

The wear-resistant refractory plastic material is made of high-alumina bauxite clinker, corundum and silicon carbide and other wear-resistant materials, combined with powder or liquid binder, and mixed with some additives. It has excellent wear resistance at high temperature. Plastic.

Wear-resistant refractory plastics are classified into NMK-Ⅰ and NMK-Ⅱ according to their physical and chemical properties. N, M, and K respectively represent resistance, grinding, and three Chinese characters.

|

Product name |

Corundum (silicon carbide) wear-resistant refractory plastic |

|

Index |

MNK-Ⅰ |

NMK-Ⅱ |

|

Bulk density(110℃±5℃X24h) |

Kg/m |

≥2700 |

≥2600 |

|

Normal temperature compressive strength |

(110℃±5℃X24h) |

≥30 |

≥50 |

|

MPa |

800℃X3h |

≥80 |

≥70 |

|

Normal temperature flexural strength |

(110℃±5℃)X24h |

≥10 |

≥9 |

|

SPa |

800℃X3h |

≥15 |

≥12 |

|

Thermal shock stability(900℃,Water cooling) |

Times |

≥20 |

≥20 |

|

The rate of change after burning, the temperature of the test is not more than ±1% of the test temperature for 3 hours |

℃ |

1300 |

1300 |

|

Wear resistance(900℃X6h) |

cm3 |

≤8 |

≤9 |

|

Plasticity index |

% |

15~40 |

15~40 |

|

Refractoriness |

℃ |

≥1770 |

≥1770 |

|

Al2O3 |

% |

≥70 |

≥50 |

|

SiC |

% |

— |

≥30 |

It is suitable for the cyclone cylinder of circulating fluidized bed boiler, the lining of furnace wall and the part with severe impact and wear of coal ash. The wear-resistant refractory plastic material is made of high-alumina bauxite clin

中(zhōng)文

中(zhōng)文

Advisory Hotline:0371-88817899轉801-808

Advisory Hotline:0371-88817899轉801-808