Wear-resistant refractory castables are made of high-alumina bauxite clinker, corundum and silicon carbide and other wear-resistant raw materials, with aluminate cement as binder and external additives. An excellent refractory castable, a material that is formed by casting or vibration.

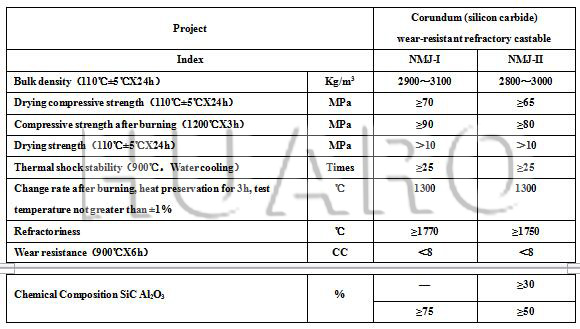

Wear-resistant refractory castables are classified according to rationalization performance: NMJ-I, NMJ-II.N, M, and J represent the three words of resistance, grinding and pouring.

|

Project |

Corundum (silicon carbide) wear-resistant refractory castable |

|

Index |

NMJ-I |

NMJ-II |

|

Bulk density(110℃±5℃X24h) |

Kg/m3 |

2900~3100 |

2800~3000 |

|

Drying compressive strength(110℃±5℃X24h) |

MPa |

≥70 |

≥65 |

|

Compressive strength after burning(1200℃X3h) |

MPa |

≥90 |

≥80 |

|

Drying strength(110℃±5℃X24h) |

MPa |

>10 |

>10 |

|

Thermal shock stability(900℃,Water cooling) |

Times |

≥25 |

≥25 |

|

Change rate after burning, heat preservation for 3h, test temperature not greater than ±1% |

℃ |

1300 |

1300 |

|

Refractoriness |

℃ |

≥1770 |

≥1750 |

|

Wear resistance(900℃X6h) |

CC |

<8 |

<8 |

|

Chemical Composition SiC Al2O3 |

% |

— |

≥30 |

|

≥75 |

≥50 |

It is suitable for the lining of high temperature parts such as cyclone furnace and coal-fired furnace refractory belt. Wear-resistant refractory castablesare made of high-alumina bauxite clinker, corundum and silicon carbide and other wear-

中(zhōng)文

中(zhōng)文

Advisory Hotline:0371-88817899轉801-808

Advisory Hotline:0371-88817899轉801-808