|

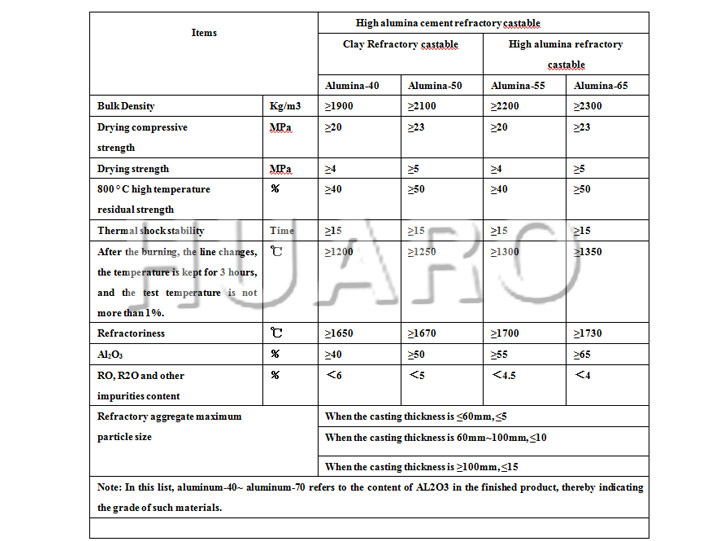

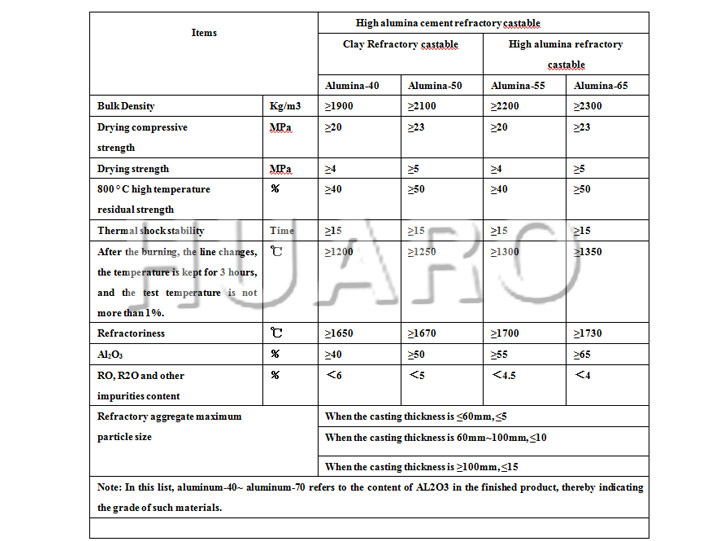

Items |

High alumina cement refractory castable |

|

Clay Refractory castable |

High alumina refractory

castable |

|

Alumina-40 |

Alumina-50 |

Alumina-55 |

Alumina-65 |

|

Bulk Density |

Kg/m3 |

≥1900 |

≥2100 |

≥2200 |

≥2300 |

Drying compressive

strength |

MPa |

≥20 |

≥23 |

≥20 |

≥23 |

|

Drying strength |

MPa |

≥4 |

≥5 |

≥4 |

≥5 |

800 ° C high temperature

residual strength |

% |

≥40 |

≥50 |

≥40 |

≥50 |

|

Thermal shock stability |

Time |

≥15 |

≥15 |

≥15 |

≥15 |

|

After the burning, the line changes, the temperature is kept for 3 hours, and the test temperature is not more than 1%. |

℃ |

≥1200 |

≥1250 |

≥1300 |

≥1350 |

|

Refractoriness |

℃ |

≥1650 |

≥1670 |

≥1700 |

≥1730 |

|

Al2O3 |

% |

≥40 |

≥50 |

≥55 |

≥65 |

RO, R2O and other

impurities content |

% |

<6 |

<5 |

<4.5 |

<4 |

Refractory aggregate maximum

particle size

|

When the casting thickness is ≤60mm, ≤5 |

|

When the casting thickness is 60mm~100mm, ≤10 |

|

When the casting thickness is ≥100mm, ≤15 |

|

Note: In this list, aluminum-40~ aluminum-70 refers to the content of AL2O3 in the finished product, thereby indicating the grade of such materials. |

|

|